| Temperature range | -30°C …+70°C |

| Bending radius min. | min. 10 x D |

| Oil resistance | |

| Conductor resistance | effective capacity (core/core)

0.75 mm² max. 26.0 Ω/km – 120 nF/km 1.0 mm² max. 19.5 Ω/km – 130 nF/km 1.5 mm² max. 13.3 Ω/km – 140 nF/km 2.5 mm² max. 7.98 Ω/km – 160 nF/km |

| Insulation resistance min. | min. 20 MΩ x km |

| Test voltage | 0.75 mm² 1200 V

1.0 mm² 1200 V 1.5 mm² 2500 V 2.5 mm² 2500 V |

| Operating voltage max. | max 300 V |

| Standards | TSE K 178, DIN VDE 0812 |

| Fire performance | Vertical flame propagation EN 60332-1-2

Corrosive gas EN 60754-1/2 Smoke density EN 61034-2 Continuity of flow IEC 60331-21 FE180 Continuity of flow EN 50200 PH120 |

| EU declaration of conformity | LVD Low Voltage Directive 2014/35/EU

RoHS Restriction of Hazardous Substances 2011/65/EU |

Used to control and supply power to devices that must remain operational during a fire. Used in emergency lighting and operation of equipment necessary for surveillance and evacuation, and systems that should remain functional for a certain time, such as alarm systems (continuity of flow FE180 continuity of flow with mechanical shocks PH120). Cables are composed of halogen-free materials (flame retardant materials that do not emit toxic gas or black dense smoke that lowers visibility). They are primarily used in highly populated areas that should have fire resistance, such as smart or semi-smart buildings, housing complexes, hospitals, cinema halls, theatres, schools, shopping malls, airports, factories, etc.

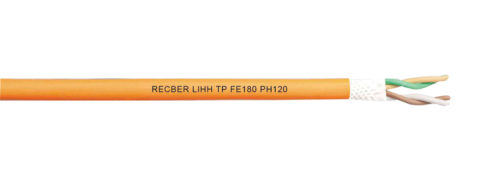

Conductor Stranded copper wire Class 5, IEC 60228

Insulation Halogen-free, cross-linked insulation, In compliance with DIN 47100 insulation colour coding EI8 EN 50363-5

Separator tape Pet tape min. 100% coverage Fibreglass tape min. 100% coverage

Sheath HFFR, RAL 2003 Orange 70°C EN 50290-2-27, HM2 DIN VDE 0207-24