|

Construction Products Regulation 305/2011/EU CPR This Regulation lays down rules for placement and availability on the market of construction products by establishing harmonised rules on declarations of performance for construction products in relation to their essential characteristics and CE marking rules for those products. Fires breaking out in buildings lead to a great number deaths due to gas and smoke intoxication. Average time from the start of fire up to flashover (ignition of pyrolysis gases) has dramatically declined over the last several decades. With this time dropping from 15 minutes in 1950s down to 5 minutes in 1985 and 3 minutes in 2010, time needed to evacuate the building on fire has decreased substantially. These trends have urged the construction product manufacturers to make technological advancements and enhance fire performances. |

|

|

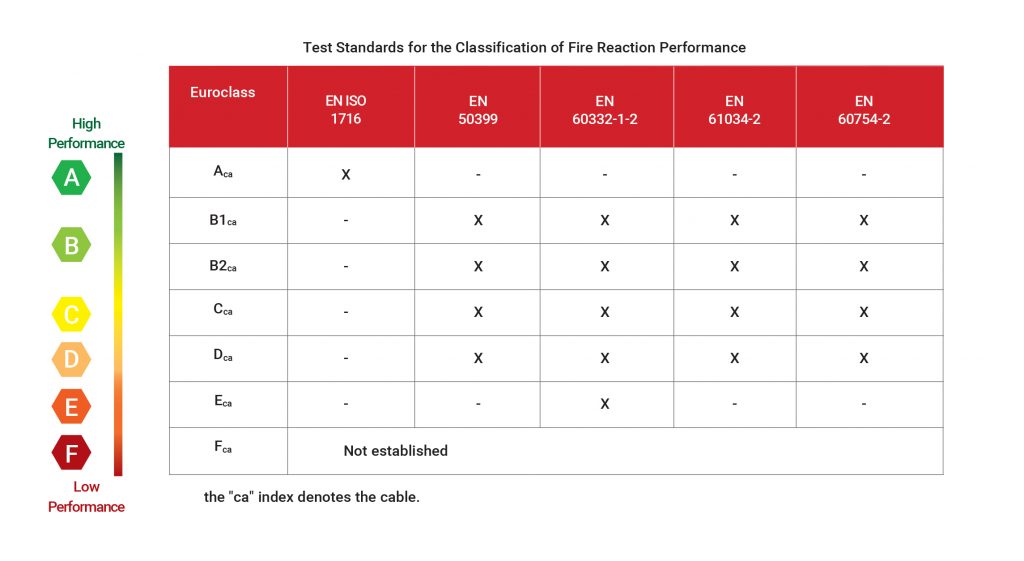

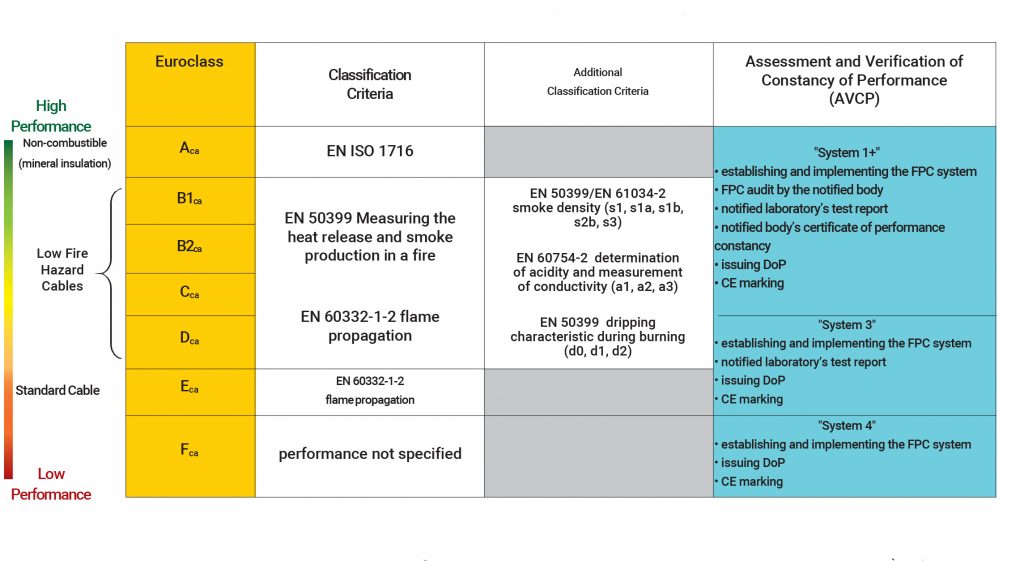

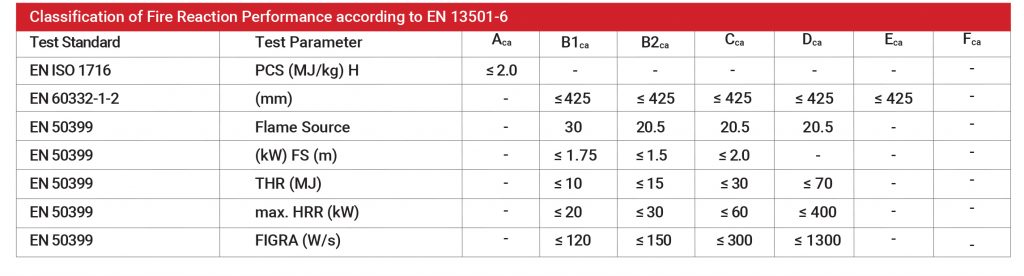

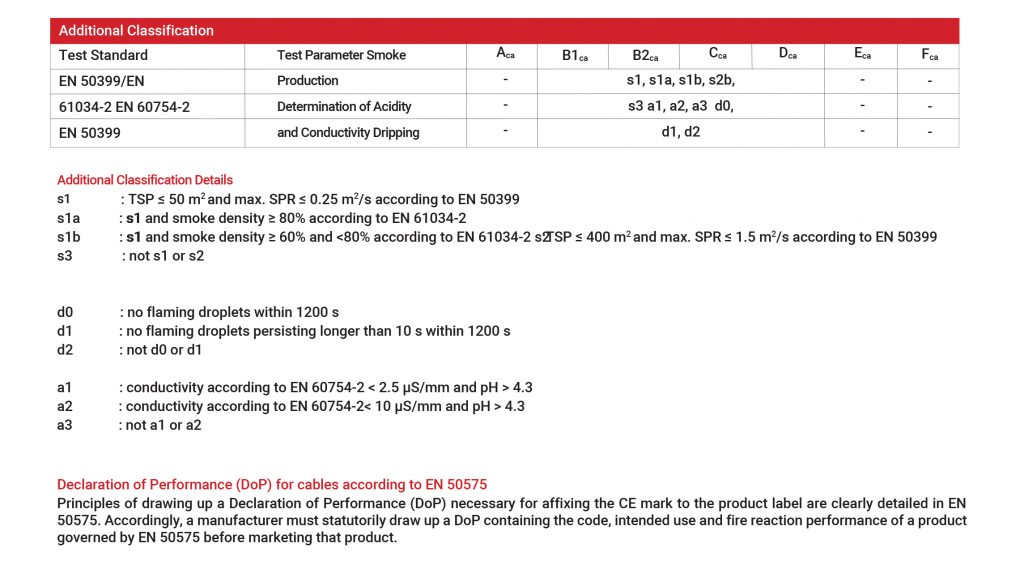

Cables are one of the most widely used materials in modern constructions. On March 9, 2011, the European Parliament and European Council decided that power, control and communication cables used in establishment of fixed installations in constructions including buildings and infrastructures would be governed by CPR in order to limit the formation and propagation of flame and smoke in case of fire in a building, minimize loss of life and property, evacuate building occupants in safety and safely respond to fire. Instead of introducing a criteria for performance levels to be fulfilled by cables used in constructions, CPR leaves it to each country to establish the performance and safety class for cables.In this respect, the regulatory and supervisory body is the Ministry of Environment and Urbanization. Fire reaction performance of cables is regulated by the local regulatory body. This body determines the minimum cable requirements according to EN 13501-6 based on construction type, characteristics and application. CPR does not prescribe a statutory performance class for cables.It only specifies the fire reaction performance criteria that should be satisfied by cables. Moreover, the directive requires the statement of fire reaction performance and CE marking for cables used in constructions. The regulatory transition process began on July 1, 2016, and final effective date of the directive will be July 1, 2017 at the latest. The directive leaves it to authorized agencies of each country to manage the transitional process. In other words, such agency may optionally issue a circular and set an effective date earlier than July 1, 2017 for its country. Suppliers intending to export cables to EU countries must legally request from the manufacturer to issue a Declaration of Performance (DoP) and affix a CE mark as described in EN 50575 to the product or the product’s label. Providers failing to satisfy this procedure may not put their products on the market. Fire Reaction Performance Requirements for Cables Used in Constructions The standard published in September 2014 specifies requirements for the fire reaction performance as well as methods for testing and assessment and compliance assessment criteria for power, control and communication cables used in a building. EN 50575 standard does not specify any electrical, mechanical and environmental requirement for the cables, and does not override other standards. The standard only relates to fire reaction classes of cables. Requirements for CE marking must be satisfied for cables covered by this standard and CE marking of such cables is mandatory. Electrical, communication, fire detection and alarm cables that require uninterrupted line supply in buildings and other constructions as well as cables used in security facilities requiring uninterrupted signal supply, such as firefighting systems, are outside the scope of EN 50575 standard. EN 50575 standard relates to Construction Products Regulation (305/2011/EU) and mandatory CE marking.

|

|

|

|

|

|

Cables are classified according to the Assessment and Verification of Constancy of Performance (AVCP) System as follows.

|

|

|

System 1+ These cables are classified in Aca, B1ca, B2ca and Cca categories. The manufacturer carries out the factory production checks (FPC) and class determination tests. The notified body carries out the initial type test to determine fire reaction performance, determines the product class based on this test, audits the place of production and initial FPC, and constantly monitors and assesses FPC.Based on the certificate of performance constancy issued by the notified body, manufacturer draws up the declaration of performance (DoP) and affixes CE mark according to EN 50575. System 3 These cables are classified in Dca and Eca categories. The manufacturer carries out the factory production checks (FPC) for these cables, but it is the responsibility of the accredited test laboratory to take samples to determine the fire reaction performance, carry out the initial test and identify the product type accordingly.Based on the test report issued by the notified laboratory, manufacturer draws up the declaration of performance (DoP) and affixes CE mark according to EN 50575. System 4 These cables are classified in the Fca category. The manufacturer carries out the factory production checks (FPC),and also draws up the declaration of performance (DoP) and affixes CE mark according to EN 50575. |

|

|

PCS – Gross Calorific Value H – Flame Propagation EN 60332-1-2 FS – Flame Propagation EN 50399 |

HRR – Heat Release Rate THR – Total Heat Release SPR – Smoke Production Rate |

TSP – Total Smoke Production FIGRA – Fire Growth Rate Index |

|

|

||

|

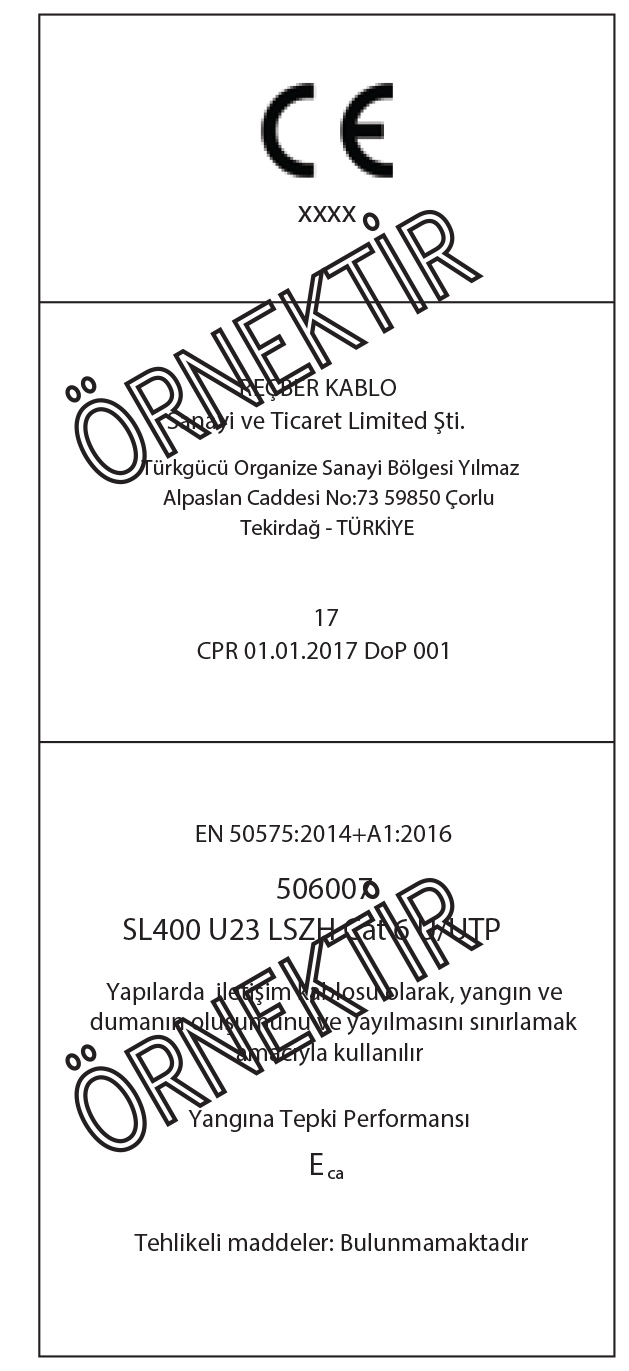

CE Marking in Cables According to EN 50575 Principles for affixing the CE mark to the product label are clearly detailed in EN 50575. • The product or label may not contain CE marking unless a declaration of performance (DoP) is issued for the product. • CE mark shall be prepared by the manufacturer in line with the format and content prescribed by the standard and affixed visibly, legibly and indelibly to the product labels on reels or coils. • CE marking signifies compliance with applicable legislation and serves as a passport for free circulation of the product within the European marketplace. • CE marking under the Low Voltage Directive (LVD) is based on the manufacturer’s own statement, however in CE marking under CPR, a more efficient system involving the concepts of “Notified Body and Notified Laboratory” has been established.

EN 50399 Heat Release and Smoke Generation Measurement On Cables During Flame Propagation Test As fire propagation, smoke generation and flaming droplets substantially affect fire safety, performing fire tests as per EN 50339 to avoid loss of life and property in case of fire, plays an important role in selecting fire-safe cables. The EN 50399 test apparatus is used to measure the fire reaction of cables mounted on a ladder in the vertical plane.In addition to the rig in EN 60332-3-10, the test system also allows the measurement of heat produced, smoke released, oxygen consumed and carbon dioxide produced during the test. Hence, while recording the data generated since the cable first flamed, measurement of the flame propagation and heat release helps to determine the influence of the fire to the surrounding area, and smoke measurement helps to identify the effect of smoke on visibility reduction. Number of cables mounted to the ladder is determined based on cable diameter. Cables must be mounted tightly to the ladder individually (unbundled) with no contact. A 20.5/30 kW flame is applied with a burner. Air supply blows air into the chamber at a flow rate of 8000 ± 400 L/min. Test duration is 25 minutes and flame application time is 20 minutes. |

|

|

|

|